The way that I check centrality of the small end eyes in the crank case bores is to use a digital vernier, rotate the flywheel assembly so that the small ends are level with the tops of the crank case bores and then push the rods away from the side to be measured and use the digital vernier to measure the distance. Repeat for the other side of the same rod and then do the same for the other rod. I cannot give you measurements as it depends upon whether you have standard liners, 90 bore or whatever. Given the four measurements you will be able to work out whether you need to put a shim between the drive side flywheel and the inner of the drive side main bearing. I helped Dick Sherwin to do this a couple of weeks ago and with the help of a 10 thou shim all measurement were the same to within about one thou. It would not be normal to get all the measurements to be so close together but his crankcase was recently trued up by Goddens. If you do need shims then the one that fits inside the gearbox on the mainshaft fits standard sized mainshafts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ET77 Main bearing distance piece

- Thread starter craig

- Start date

A word on main bearings and their quality . First off , the original quality bearings fitted when built were adequate for the needs .

What causes them to walk inwards is having poorly alligned flywheels . The factory allowed up to 2 thou total runout but it's of little consequence when shift at the crankpin occurs . All bets are off . The mains will then move inwards as a result of the motion produced , the main shafts having a motion not unlike Marylin Monroe's hips . Think about it . More to come . Sid .

What causes them to walk inwards is having poorly alligned flywheels . The factory allowed up to 2 thou total runout but it's of little consequence when shift at the crankpin occurs . All bets are off . The mains will then move inwards as a result of the motion produced , the main shafts having a motion not unlike Marylin Monroe's hips . Think about it . More to come . Sid .

I respectively disagree as outer races for an untouched factory engine have lost fit and are loose. You are quite correct in saying an untrue flywheel would only make matters worse..... but the sand cast porous alloy in the Vincent cases was NOT up to the job.

One can carefully remove the outer race from a case that has NEVER been used and find the the cases have stretched beyond the fit needed to hold the races in place.

One can carefully remove the outer race from a case that has NEVER been used and find the the cases have stretched beyond the fit needed to hold the races in place.

Thank you timetraveller, This procedure of checking the rod ends to the crankcase cylinder bore is what i had envisioned. Indeed it does not sound reasonable that this centralization workout to .001" tolerances, but I will see what I get.

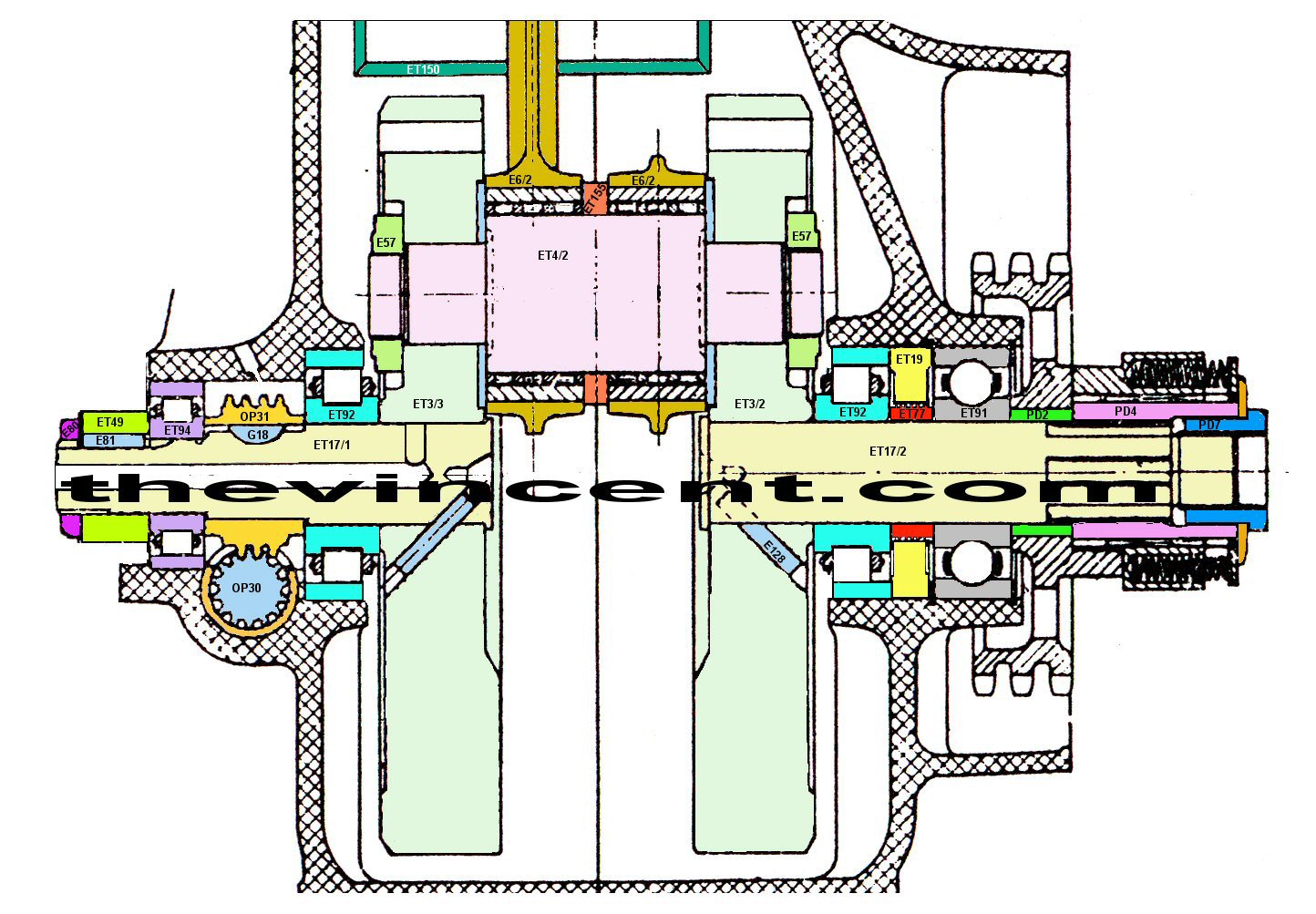

I am concerned about the ET92 rollers being positioned at the very edge of their respective outer races, as shown in my drawing. It would seem more stable to move the inner roller set outward and into the center of the outer race. Should there be any effort to centralize the ET92 roller sets? Thank you for any help around this.

Cheers

Craig

I am concerned about the ET92 rollers being positioned at the very edge of their respective outer races, as shown in my drawing. It would seem more stable to move the inner roller set outward and into the center of the outer race. Should there be any effort to centralize the ET92 roller sets? Thank you for any help around this.

Cheers

Craig

The way that I check centrality of the small end eyes in the crank case bores is to use a digital vernier, rotate the flywheel assembly so that the small ends are level with the tops of the crank case bores and then push the rods away from the side to be measured and use the digital vernier to measure the distance. Repeat for the other side of the same rod and then do the same for the other rod. I cannot give you measurements as it depends upon whether you have standard liners, 90 bore or whatever. Given the four measurements you will be able to work out whether you need to put a shim between the drive side flywheel and the inner of the drive side main bearing. I helped Dick Sherwin to do this a couple of weeks ago and with the help of a 10 thou shim all measurement were the same to within about one thou. It would not be normal to get all the measurements to be so close together but his crankcase was recently trued up by Goddens. If you do need shims then the one that fits inside the gearbox on the mainshaft fits standard sized mainshafts.

If you think about it, having the inner of the ET92s close up against the flywheels makes for a very stiff assembly so I would not recommend moving the whole bearing over. Vincents used special bearings with one side of the outer race ground back to give clearance with the crankpin nuts. What people have been doing over the last decade or two is to machine one side of the ET19 back to allow use of a full width outer race, pushed outwards so that there is now more bearing face between the outside of this race and the crankcase main bearing housing. This means that the rollers now run offset from the centre of outer race but that does not seem to be causing any problems. I would not want to argue with Rip Tragle. He tells us that he has only built road bikes but that some of these were so fast that a 150 mph Shadow speedo was not adequate and he had to resort to Lightning 180 mph speedos. I have to tell you that most of us could not do that. So he might be correct about the inadequacies of sand cast crankcases but I would still check the fit of the old bearings first before resorting to line boring the whole lot. If the bearings are loose then there is a very nice and elegant mod that was put into this Forum some time ago by ex-editor of MPH, Robert Watson. It consists of a new steel flanged housing for the drive side with the flange on the outside (ESA side). This takes two back to back taper roller bearings to support the mainshaft and houses an oil seal on the outer side. It is a nice way of saving a drive side crankcase and is probably a better scheme than the original.

Hello All, There is a main bearing you can buy that has a lip on the outside track, So even if it was not very tight there is noway it can come out, The rollers stop it, That is what we used on the last engine I helped with. It is all very well sending your cases away to be bored, But some people can't do a good job, Then you are stuffed ! Cheers Bill.

Thanks TimeT and Bill, There is not enought detail to fully understand your suggestions. Would you please be so kind as to find and report the details around ?

1) Robert Watson tapered roller conversion for drive side

2) Main bearing with a lip

3) full width outer race for ET92 on drive side

Also anybody know the bore offset for a Vincent twin please? Cheers Craig

ps - my old outer race of ET92 on the drive side that walked out was very curved on both outer edges.....offsetting and reducing its actual support by about 1/3.

1) Robert Watson tapered roller conversion for drive side

2) Main bearing with a lip

3) full width outer race for ET92 on drive side

Also anybody know the bore offset for a Vincent twin please? Cheers Craig

ps - my old outer race of ET92 on the drive side that walked out was very curved on both outer edges.....offsetting and reducing its actual support by about 1/3.

Last edited:

An interesting point made by Rip about bearing fits in un used NOS virgin cases . Never had the opportunity to notice this not having stripped unrun NOS cases nor do I know of anyone who has done so . I do have in hand a complete twin axcess door with all parts intact , never used NOS , and those bearings within it are still tightly in place . A different alloy tho . Must have been some reason Rip had to remove them , corroded ? Maybe he will expand upon this . Sid .