Matty, the top hat bushes that the layshaft runs in MUST be Oilite, as you've discovered, as should the internal bushes on the output sleeve gear. I was talking about the phosphor-bronze bushes ON the layshaft itself. Cheers mate.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Burman 4th Gear Selector Meltdown

- Thread starter tatty500

- Start date

having removed the final drive sprocket the retaining circlip was unseated this quite likely will have allowed the bearing to walk with corresponding axial movement in the final drive gear. fortunately the gear box housing for the bearing has not wallowed out and the bearing seems a tight fit. however, part of the outer lip of the gear box circlip groove fell away which is obviously allowing the circlip to become unseated.

I can't understand this type of failure other than by ham fisted dismantling applying unnecessary heavy axial load via the main shaft and resultant knock on effect. in mitigation I can say I had not been into the gearbox prior to 4th gear not engaging. Anyhoos, long wait envisaged as welder and machinist coordinate works.

" 'tis business of the wealthy man to give work to the artisan" , only problem with that adage is I ain't rich.

thoughts on using an angular bearing on the out put gear ?

yes, i also had great success with the Brightspark condenser replacemnt on a BSA at the fraction of the price of a mag' condenser replacement and rebuild. Totally recommend it.

I can't understand this type of failure other than by ham fisted dismantling applying unnecessary heavy axial load via the main shaft and resultant knock on effect. in mitigation I can say I had not been into the gearbox prior to 4th gear not engaging. Anyhoos, long wait envisaged as welder and machinist coordinate works.

" 'tis business of the wealthy man to give work to the artisan" , only problem with that adage is I ain't rich.

thoughts on using an angular bearing on the out put gear ?

yes, i also had great success with the Brightspark condenser replacemnt on a BSA at the fraction of the price of a mag' condenser replacement and rebuild. Totally recommend it.

Because I had my Comet for such a long time, Before the case broke, Where the circlip is,

I think my trouble was from my Big Boot !, And a bit of Racing.

I would get the welding done with the circlip still in ?, Or it will be tricky to get the groove back ?.

That is what I did, And bought a new circlip because the heat will mess up the old one ?.

I filed up the weld by hand, So it only cost me the welding.

Good Luck, Bill.

I think my trouble was from my Big Boot !, And a bit of Racing.

I would get the welding done with the circlip still in ?, Or it will be tricky to get the groove back ?.

That is what I did, And bought a new circlip because the heat will mess up the old one ?.

I filed up the weld by hand, So it only cost me the welding.

Good Luck, Bill.

Hi Brian

Seems you have found the root cause of your problem.

Obviously welding the box and cutting a new groove for the circlip is the best solution, but it is probably possible to put some screws round the groove area, the heads of which overlap the groove to hold the circlip in.

This could be quite a simple "bodge" and would only involve drilling and tapping a few small holes in the aluminium casting.

I do not believe there should be much force on the circlip trying to push it out UNLESS there is a taper on the dogs, but if they are properly engaged the force should not be that great.

I suspect that in the past someone has not fitted the circlip fully into the groove - I have always tapped mine round to make sure. If part of the circlip is not in the groove then it will be at an angle and able to be forced out and break the flange off.

Hopefully another problem understood and possibly solved one way or another.

Matty

Seems you have found the root cause of your problem.

Obviously welding the box and cutting a new groove for the circlip is the best solution, but it is probably possible to put some screws round the groove area, the heads of which overlap the groove to hold the circlip in.

This could be quite a simple "bodge" and would only involve drilling and tapping a few small holes in the aluminium casting.

I do not believe there should be much force on the circlip trying to push it out UNLESS there is a taper on the dogs, but if they are properly engaged the force should not be that great.

I suspect that in the past someone has not fitted the circlip fully into the groove - I have always tapped mine round to make sure. If part of the circlip is not in the groove then it will be at an angle and able to be forced out and break the flange off.

Hopefully another problem understood and possibly solved one way or another.

Matty

PS

I do not think a taper roller bearing would be necessary or suitable because these can move around if not preloaded, and in any case a ball bearing is designed to take lateral loads. This is why there is one big ball bearing on the crankshaft fixed laterally, when the other 3 are normal rollers which can float in and out.

Velocettes for instance have 2 taper roller main bearings which have to be carefully set up with a specified preload to prevent end float.

All the best

Matty

I do not think a taper roller bearing would be necessary or suitable because these can move around if not preloaded, and in any case a ball bearing is designed to take lateral loads. This is why there is one big ball bearing on the crankshaft fixed laterally, when the other 3 are normal rollers which can float in and out.

Velocettes for instance have 2 taper roller main bearings which have to be carefully set up with a specified preload to prevent end float.

All the best

Matty

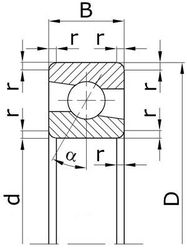

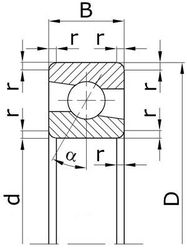

just to make sure there's no misunderstanding, it is an angular ball roller bearing and not a tapered roller bearing I was considering. However, the concern regarding if the angular ball roller needs to be preloaded was the reason for my query.

As I understand although the deep groove caged ball bearing will accept an amount of lateral load would an angular ball roller not be better suited when considering the additional lateral loads imposed by the primary drive.

Would this method have been available at the time of production, would it have been considered an unnecessary additional cost factor?

26207К Angular Contact Ball Bearings dimensions

New Designations :

26207К

Main demensions :

37 × 72 × 17

Bore Dia × Outside Dia × Width Dia (mm)

As I understand although the deep groove caged ball bearing will accept an amount of lateral load would an angular ball roller not be better suited when considering the additional lateral loads imposed by the primary drive.

Would this method have been available at the time of production, would it have been considered an unnecessary additional cost factor?

26207К Angular Contact Ball Bearings dimensions

New Designations :

26207К

Main demensions :

37 × 72 × 17

Bore Dia × Outside Dia × Width Dia (mm)

Don't waste your time Brian trying to fix a problem that doesn't exist.

Angular contact bearings are typically used as pairs as axial thrust in the wrong direction can make them fall apart.

If you do the standard calculation for a deep grove ball bearing race you'll find it has ample capacity to withstand the sort of loads your gearbox carries.

Angular contact bearings are typically used as pairs as axial thrust in the wrong direction can make them fall apart.

If you do the standard calculation for a deep grove ball bearing race you'll find it has ample capacity to withstand the sort of loads your gearbox carries.

Hi Brian

I agree with passenger about the bearing but the bore of the "proper" bearing is in fact 1.5 "(Imperial ) - I can not imagine why !!

I qualified as an Electrical/electronic Engineer in 1957 with a few low level endorsements in mechanical engineering, am now rather out of date on the latest developments so can not really comment with any authority on the current types of bearings.

Good Luck

Matty

I agree with passenger about the bearing but the bore of the "proper" bearing is in fact 1.5 "(Imperial ) - I can not imagine why !!

I qualified as an Electrical/electronic Engineer in 1957 with a few low level endorsements in mechanical engineering, am now rather out of date on the latest developments so can not really comment with any authority on the current types of bearings.

Good Luck

Matty

Being an imperial size the 37mm bore would be some 0.043" undersize so a non starter there, without introducing additional hurdles.

It makes sense that the bearing would need to be orientated correctly but I would have thought the axial thrust is just from the gearbox side.

Whatever, all hypothetical as the bearing would not fit anyhow.

Fixing a problem wasn't my primary concern I thought I may have found a financial available solution with a possible benefit; have you seen the price of the replacement bearing, if you can get it!

It makes sense that the bearing would need to be orientated correctly but I would have thought the axial thrust is just from the gearbox side.

Whatever, all hypothetical as the bearing would not fit anyhow.

Fixing a problem wasn't my primary concern I thought I may have found a financial available solution with a possible benefit; have you seen the price of the replacement bearing, if you can get it!

Brian,

I still have a spare brand new SKF Explorer bearing in it's box of that size which I have had professionally ground out to 1.500". It is the double rubber sealed type; you can choose to leave it that way, or remove one or both seals. Having seen the application, SKF advice is to keep both seals in; the outer keeps the rain and dirt out, the inner keeps gearbox debris out. They reckon it should easily last 60K to 80K miles before re-packing with grease may be required.

It's yours for £50 plus post.

Peter B

I still have a spare brand new SKF Explorer bearing in it's box of that size which I have had professionally ground out to 1.500". It is the double rubber sealed type; you can choose to leave it that way, or remove one or both seals. Having seen the application, SKF advice is to keep both seals in; the outer keeps the rain and dirt out, the inner keeps gearbox debris out. They reckon it should easily last 60K to 80K miles before re-packing with grease may be required.

It's yours for £50 plus post.

Peter B