Cripes you near confused the hell out of me............ ..............Ok if a 4 is too lean you need less of a cutaway, so lower the slide in the carb body = machine a small amount off the base of the slide to let it sit lower. A 3 is too rich, so you need to raise the cutaway to let more air in. I think the problem is that we think of the cutaway when it is sat on a flat bench and you check the cutaway with a drill or similar, but when the slide is in the body of the carb, this changes because if all is well, the slide does not sit fully down unless you do not want the engine to idle. I have never altered the needle from its middle clip groove generally. Like I said it is all a bit experimental, only plug readings will give some indication of mixture strength, if the plugs are very sooty, then you are still to rich or if the insulator is very clean and whitish/grey then you are too lean. These engines generally run rich anyway being air cooled they need a good fuel supply to run well enough and stave off detonation to some extent.

..............Ok if a 4 is too lean you need less of a cutaway, so lower the slide in the carb body = machine a small amount off the base of the slide to let it sit lower. A 3 is too rich, so you need to raise the cutaway to let more air in. I think the problem is that we think of the cutaway when it is sat on a flat bench and you check the cutaway with a drill or similar, but when the slide is in the body of the carb, this changes because if all is well, the slide does not sit fully down unless you do not want the engine to idle. I have never altered the needle from its middle clip groove generally. Like I said it is all a bit experimental, only plug readings will give some indication of mixture strength, if the plugs are very sooty, then you are still to rich or if the insulator is very clean and whitish/grey then you are too lean. These engines generally run rich anyway being air cooled they need a good fuel supply to run well enough and stave off detonation to some extent.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Amal 289 Throttle Slide Cutaways

- Thread starter Chris S

- Start date

File away I say. back in the day in the paddock at silverstone on a zero budget I have done it a few times. filing a hole in the back of a TT slide so it would tick over for road use was another trick. and dont be supprised that some jap carbs borrow dimentions from Amal I rember the stink wheel guys were always borrowing the amal main jets for their yamaha YDS god knows whats.

but of course then we had the advantage of proper petrol and Lodge plugs you could read the mixture with while wearing sun glasses .

.

but of course then we had the advantage of proper petrol and Lodge plugs you could read the mixture with while wearing sun glasses

It would be a brave man who attempted to file this by hand, with any kind of accuracy, and even doing it on a milling machine would need a fixture making to hold it without damaging the slide.

I would be tempted to use a small container of molten cerrobend, insert your slide at the appropriate angle, let it cool and clamp it in the mill.

Cerrobend is your friend. Always helpful and fun to play with.

Yes I know I can use a file, but for some unknown reason I like to complicate things. Raised by military folk and being toilet trained at gun point may have something to do with it.

I bought a Mains electric type, Like a dremal, Only about £30 to 40 , I got mine on sale for £30 from Machine Mart U.K. I have done some super tricky jobs.

I ground down 2 Delorto main jets,They are not very big !, For a Mod' for my Mk1 Concentrics, To improve the suck on the airjet hole, Don't know if it will work ?.

Not many bits come with it, But I have lots of bits from a proper dremal, Which I found stops on any sort of load. Cheers Bill.

I ground down 2 Delorto main jets,They are not very big !, For a Mod' for my Mk1 Concentrics, To improve the suck on the airjet hole, Don't know if it will work ?.

Not many bits come with it, But I have lots of bits from a proper dremal, Which I found stops on any sort of load. Cheers Bill.

Oh alright then, its fine to file it! I must go out to the shed and have a go.

Bloomin' peer pressure got me again.

Bloomin' peer pressure got me again.

Would it be possible to just hold the slide by hand and carefully use a fine belt linisher to sand down to the marked line on the slide?Oh alright then, its fine to file it! I must go out to the shed and have a go.

Bloomin' peer pressure got me again.

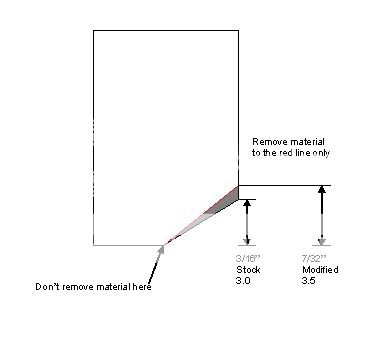

Some time ago I found an article stating the Mikuni VM was based on the AMAL concentric. The numbers on the Mikuni's jets like AMAL are based on the amount of paraffin/kerosene that flows in a minute at 68 degrees F. So having read that I checked the height of the slide cut away on my Mikunis and it worked out to be based on the number of 1/16 of an inch. I have 28mm Mikunis on my Shadow and could only get 2.5 slides. Slides with larger cutaways were a special order requiring a min order of 10 slides at $40 a piece. As I only wanted a pair of 3.5 and didn't to pay $400, I just bought a pair of 2.5s and calculated how much to tip the sine plate and machine off so I didn't go beyond the point marked "Don't remove material here" . The Mikuni slides are brass and quite rigid, the slide is located so the solid portion is under the clamp. It didn't distort. Light cuts and it worked out. I have a table listing the angles/height of gauge blocks and amount to be machined off.I know nothing about Mikuni carbs, but looking on a site for Nortons, this diagram came up showing a Mikuni slide, which shows the cutaway modification,

amazingly in Imperial measurements, uncannily like those on an Amal!

It would be a brave man who attempted to file this by hand, with any kind of accuracy, and even doing it on a milling machine would need a fixture making to hold it without damaging the slide.

After going through all this at one of our section nights I was showing it to Dave Matson, who belongs to our section, he told me he just marks them and files them. So you pays your money and takes your chances I guess.

Steven

Hi there Eddy, I didn't want to say (condemn myself) but you are definitely onto something there............Would it be possible to just hold the slide by hand and carefully use a fine belt linisher to sand down to the marked line on the slide?

I ve always wanted a sanding belt now I have the perfect excuse! (Eddy, my wife just said I should tidy my shed before I buy any more kit!!)