Anyone got any specific measurement details on the cutaways on 289 carb slides?

I understood that the increase in slide cutaway was a linear measurement, but I am now questioning that.

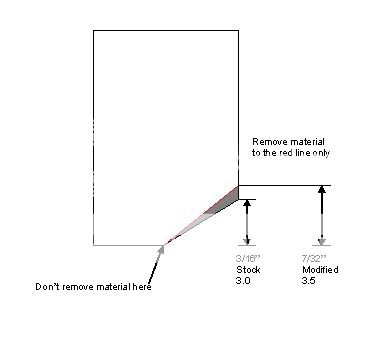

I am setting up a new set of 229/289's on my twin and ordered some 3 cutaway slides. However, the cutaway is not what I expected. I had assumed that a 3 cutaway would be 3/16'' (approx 4.7625mm) but they appear to be far less than that, nearer to 4mm.

The 4 slides that came with the carbs measure 1/4'' (4/16'' or 6.35mm) on the cutaway so I am a bit confused as it would appear that the 3 cutaway is not simply 3 x 1/16''. My understanding was that a 1 cutaway would be 1/16'' a 2 cutaway would be 1/8'' ( 2 x 1/16'') a 3 would be 3/16'' and a 4 would be 1/4'' (4/16'')

Am I missing something or simply misunderstanding the cutaway scale.

I understood that the increase in slide cutaway was a linear measurement, but I am now questioning that.

I am setting up a new set of 229/289's on my twin and ordered some 3 cutaway slides. However, the cutaway is not what I expected. I had assumed that a 3 cutaway would be 3/16'' (approx 4.7625mm) but they appear to be far less than that, nearer to 4mm.

The 4 slides that came with the carbs measure 1/4'' (4/16'' or 6.35mm) on the cutaway so I am a bit confused as it would appear that the 3 cutaway is not simply 3 x 1/16''. My understanding was that a 1 cutaway would be 1/16'' a 2 cutaway would be 1/8'' ( 2 x 1/16'') a 3 would be 3/16'' and a 4 would be 1/4'' (4/16'')

Am I missing something or simply misunderstanding the cutaway scale.