I suggest that you take note of the D rear subframe, taking care to note how the fixing bolts are aligned to the centre of the struts. Also the seat plays no part of the construction.I do not comprehend what Trevor means when he says "trying to get itself into correct geometry" it seems to me that if you go fully sprung by mounting the seat rear frame brackets onto long tubes going down to the footrest plates, then the seat supports are at an acute angle and when you sit on the seat you will create a rearward force as the seat support, at the acute angle tries to collapse to an even more acute angle as the weight is being brought to bear onto the seat, in effect the force tries, and sometimes succeeds in tearing the welds or the metal on the seat front bracket, as Timetraveller points out, the heavier the weight carried the worse the problem, especially under fierce acceleration with a heavy pillion passenger.

However if you go fully sprung by using a custom made sledge, then the seat rear frame brackets should be fixed at 90 degrees vertical to a flat horizontal surface and no forces will be introduced, of course if the seat is badly manufactured or the plywood rotten then the seat could fail however it is mounted. A few folks have addressed this problem by making the entire seat base out of Duralumin and beefing up the seat frame.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seat Failure

- Thread starter Martyn Goodwin

- Start date

I suggest that you take note of the D rear subframe, taking care to note how the fixing bolts are aligned to the centre of the struts. Also the seat plays no part of the construction.

I assumed the discussion was primarily about why when a Series B or C suspension set up is converted to a fully sprung set up, discarding the FT94AS seat stay assemblies, the seat front bracket becomes prone to fracturing. I cannot see the relevance of the Series D set up to the discussion, I assume the problem does not occur on the Series D.

There is a very easy way to understand this. Imagine taking the seat off a ‘B’ or ‘C’ and replace the two original seat stays with two lengths of rod, fastened to the rear of the pillion footrest plates and free to pivot about their lower fixings. Now imagine two pieces of string passing through the original front pivot holes and fastened to the top of each of these two rods. The only thing that would stop the rods rotating backwards if one pushed downwards on them would be the two pieces of string. That is like the ‘D’ set up. Everything is in a straight line and, ignoring any weights applied downwards on the string such as a loaded seat, and then everything is in tension. Now imagine putting two bits of steel protruding vertically about 2” from each end of the forward pivot hole and fasten the two pieces of string fastened to their upper ends. Now pull the tops of the two rear rods backwards and downwards. What will happen to the front two bits of 2” long bits of steel? Right, they are no longer vertical and that is why the seat frames fail.

There is a very easy way to understand this. Imagine taking the seat off a ‘B’ or ‘C’ and replace the two original seat stays with two lengths of rod, fastened to the rear of the pillion footrest plates and free to pivot about their lower fixings. Now imagine two pieces of string passing through the original front pivot holes and fastened to the top of each of these two rods. The only thing that would stop the rods rotating backwards if one pushed downwards on them would be the two pieces of string. That is like the ‘D’ set up. Everything is in a straight line and, ignoring any weights applied downwards on the string such as a loaded seat, and then everything is in tension. Now imagine putting two bits of steel protruding vertically about 2” from each end of the forward pivot hole and fasten the two pieces of string fastened to their upper ends. Now pull the tops of the two rear rods backwards and downwards. What will happen to the front two bits of 2” long bits of steel? Right, they are no longer vertical and that is why the seat frames fail.

Norman, I think we are singing from the same hymn sheet. A very simple way to prove the theory is to remove the front seat bolt and try and sit on the seat, the seat will immediately move rearwards and in doing so it damage your rear mudguard and remove some paint from your springboxes, best not to try it. An easier way to understand the forces involved is to compare the rear seat supports to pedal cycle cranks, if you attempt to start pedaling a cycle with each crank at TDC and BDC then you will go nowhere, it is impossible to exert any forces other than vertical forces, if you move the pedals off TDC you will immediately convert downward pressure to forward motion.

Last edited:

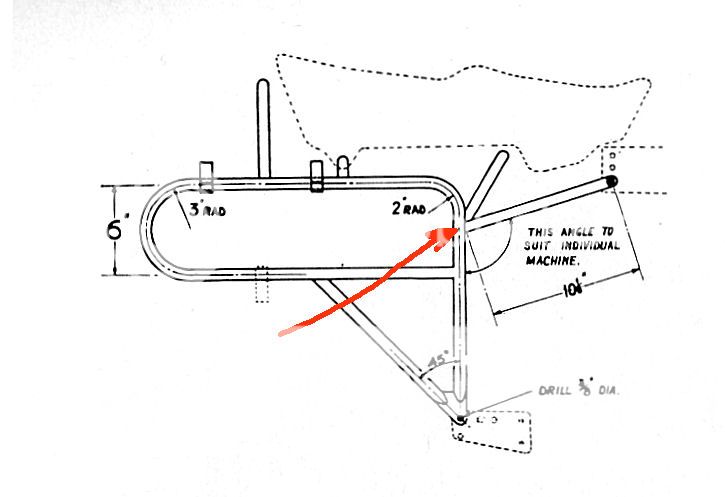

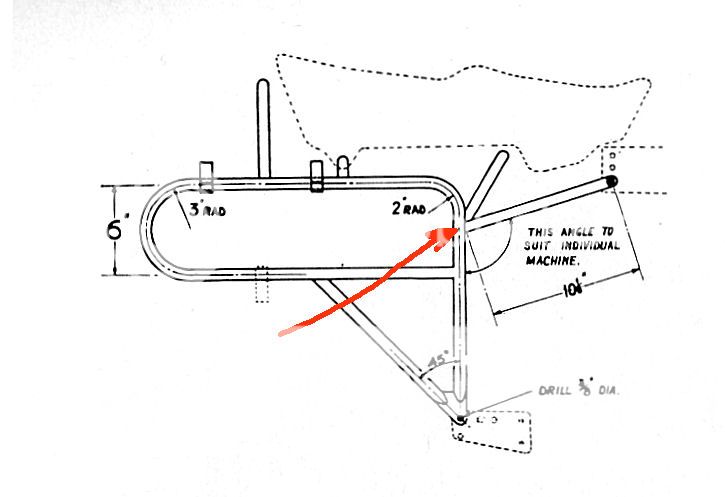

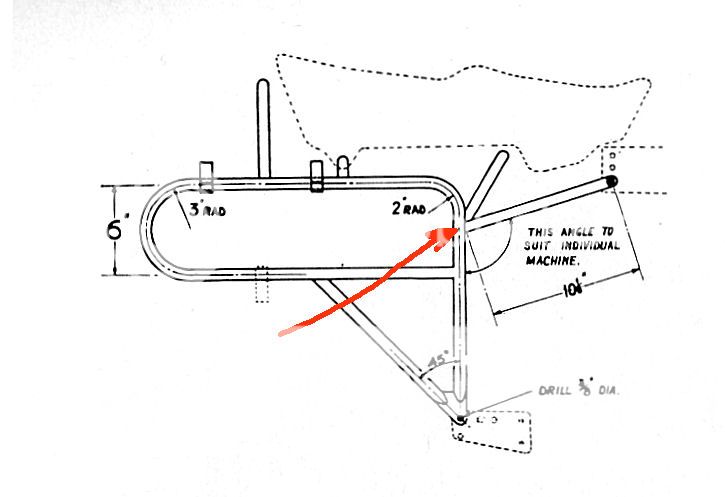

Here is the luggage rack from KTB. Eddie says quite clearly in the text it is a sub-frame designed to carry the seat as well as the luggage. I can't see how the failure described can happen, unless the welding at the point indicated has failed ??

I totally agree, the problem arises when folks go the fully sprung route by supporting the rear seat brackets using long support tubes connected to the footrest plates.Here is the luggage rack from KTB. Eddie says quite clearly in the text it is a sub-frame designed to carry the seat as well as the luggage. I can't see how the failure described can happen, unless the welding at the point indicated has failed ??

Mystery no longer. As installed on my bike the struts that are shown in Eddies design from the front of the rack connecting to the shaft that carries the horn (on a comet) were missing and thus the effect on the seat frame was exactly the same as a long strut connecting the rear seat mount to the pillion peg plates.the mystery is that Martyn says he used this design ???

I obtained a replacement seat frame (thanks Jacko) and also fitted the missing struts. All is now as strong as an ox.

Martyn

Great to see you got that sorted MartynMystery no longer. As installed on my bike the struts that are shown in Eddies design from the front of the rack connecting to the shaft that carries the horn (on a comet) were missing and thus the effect on the seat frame was exactly the same as a long strut connecting the rear seat mount to the pillion peg plates.

I obtained a replacement seat frame (thanks Jacko) and also fitted the missing struts. All is now as strong as an ox.

Martyn