As T.T. says, My Outfit was not leaning over !!. Cheers Bill.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FF: Forks Modified Steering Stem

- Thread starter greg brillus

- Start date

When I was a Jag' Mechanic, I used an electric wheel balancer, We had a lot of trouble with new tyres, They were not round !!, It was funny to see them get to a certain speed before they went into a big wobble, No amount of weights could stop the trouble on the road, You could get them better, But not good enough. Like he says, Everything has to be right, Or wrong in our case !!. Cheers Bill.

Great point, Bill-

You triggered a memory from the '70s, when I worked for the US Lotus importer, that was the Europa era.

We had problems eliminating an over the road suspension vibration issue, which varied from mild to quite severe.

A dynamic tire balancer was always used to repeatable perfection, but with less than perfect (unacceptable) road test results.

The issue was put down to the weight of the body vs the weight of the suspension, sprung vs unsprung weight, by comparison the suspension weighed too much.

I think the Special weighed in at around 1700 lb. (as comparison a caddie of the era was around 5000 lbs)

We ended up using a tire lathe; the car would be road tested to warm the tires, driven back into the shop bay, front end jacked up, lathe rolled under, and the tires cut.

Rubber scrap from a tire truing ranged from enough to hold in your palm to enough to fill a bushel basket, a truely impressive range.

The tires were then rebalanced, and problem solved. (I believe the tires were Japanese Dunlops)

Two thoughts I recall having back then- did caddie dealers even bother to balance tires and, what did Lotus owners do when they got new tires, I don't recall ever finding a tire lathe at the local tire stores.

But bottom line, as you say, is that tires are definitely not all round, and worth checking.

Best-

George

Yes John, And off the line also, Did you see that V8 bike do it, Once again the bike was not leaning over, We still don't know for sure, It's a few things that all go together, I still think the Hydraulic Damper hides most faults.

I don't want to ride a Standard bike again, I was testing a twin with H/Damper the other day, And Ron was on his Comet, We were going to do a few miles then swop, I was not happy with the twin, So I rode it home !!, A bit of luck for me ??.

Ron got to ride the Twin last Friday, And I was behind in my Honda Car !, He was like a dog with 2 tails !!, He has not had a Twin for a few years.

Good times. Cheers Bill.

I don't want to ride a Standard bike again, I was testing a twin with H/Damper the other day, And Ron was on his Comet, We were going to do a few miles then swop, I was not happy with the twin, So I rode it home !!, A bit of luck for me ??.

Ron got to ride the Twin last Friday, And I was behind in my Honda Car !, He was like a dog with 2 tails !!, He has not had a Twin for a few years.

Good times. Cheers Bill.

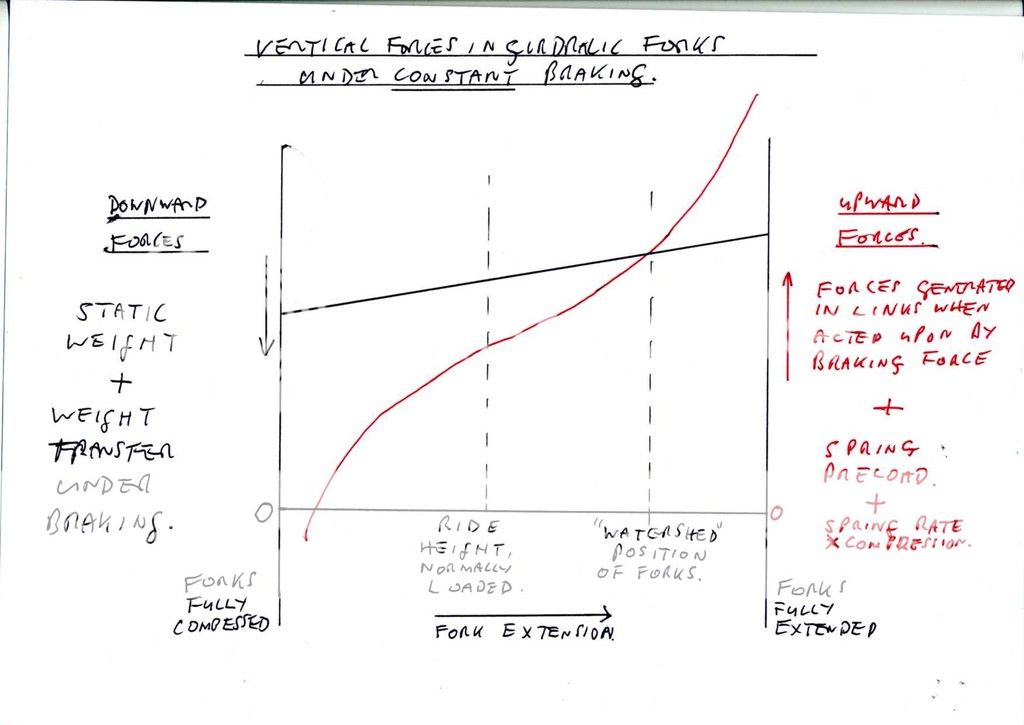

This is my model of opposing vertical forces in the forks. I have not thought about this in detail for a while, so I hope I have not made any howlers.

To the right of the point where the two force lines intersect, lift forces exceed downward forces and the forks will probably go into vertical oscillation or lock up. I have called this the “watershed position”.

As I have said, I cannot see that the angle of the bottom link is the sole determinant of this watershed position.

Some observations:

- This is at constant braking force. Note that the braking force magnitude effects both up and down forces. But we know from experience that harder braking increases up forces more than down. So the watershed point moves leftwards if braking is increased.

- Plainly increasing the ride height setting means that the forks spend more time in closer proximity to the watershed point and the probability of problems increases. Without knowing the exact shape of the force lines, how close is too close cannot be judged.

- Decreasing spring preload moves the whole lift curve downwards, so the watershed moves to the right, away from the ride height fork position. David’s short stiff springs and my degressive springs both lower preload of course.

- The JE geometry will still generate some lift I think, but testing clearly indicates that either the watershed point is far enough to the right to perhaps hardly ever be reached, or even that lift never exceeds weight so there is no force curve intersection point.

- I have no clear idea of the shape of the lift force line!!!!!! It is certainly not a straight line. I did get my model working, and it was broadly of the form shown, but the lift forces were so high my force vector analysis was clearly wrong, in detail at least.

- I think that when the forks are heavily compressed the vertical forces generated by the links may become downwards. But whether this can exceed the spring forces to produce a net downward force that adds to the other downwards forces I don’t know. I suspect it does not matter.

- As we have discussed, braking is not the only cause of a rearward force on the forks. I think an out of line wheel touching down must produce a sizeable rearwards kick in addition to the sharp turning moment impulse on the forks. The necessity with the standard geometry forks in an extended position for the wheel to move forwards in order to ride up over a bump has also been mentioned. Undoubtedly a bump generates a rearward impulse whatever the fork geometry. But the magnitude must largely depend on speed and the ratio of bump height to wheel diameter. If you were to ride over a kerb at 60 miles an hour, this is going to be a sizeable impulse force. But for more normal sized and more sloping bumps, I can’t see that the force is large enough for the difference in fork geometry to have a significant effect. I may be totally wrong of course. But the need for the wheel to move forward by an additional 0.5 inch when at 60 mph it is already moving forwards at 1056 inches per second doesn’t seem important.

I heartily agree. I did not dare make any suspension changes, rear or front, until I had fitted one.I still think the Hydraulic Damper hides most faults.

I don't want to ride a Standard bike again, .

Getting back to out of round tyres, Most rims I have seen have some out of roundness, Where the weld is.

I have just picked up a pair of old wheels from the 50 s/60/s, For my next project, And one hub was not dead centre, I had a wheel built some years ago with the same fault, The out of round rim must make the tyre out of round also ?.

So there are two things to start the ball rolling, Of the forks shaking !!. Cheers Bill.

I have just picked up a pair of old wheels from the 50 s/60/s, For my next project, And one hub was not dead centre, I had a wheel built some years ago with the same fault, The out of round rim must make the tyre out of round also ?.

So there are two things to start the ball rolling, Of the forks shaking !!. Cheers Bill.

Bill, there is a vast difference in the quality of rims, some are very good and some are really rubbish, I've seen them with a 3 or 4mm kick where the weld is, I remember trying to do a HD Sportster rim for a friend and was getting nowhere until I realised the rim itself was wider where the outer spoke holes were punched in (they were in the side flats not in the middle raised section) all I could do was average the bumps out. My own I try to get within 1mm.

Chris.

Chris.

So you build wheels too !!, Shame I am so far away, Looks like my 560cc is now going to be just a 500 !, Just picked up a standard crank, I think it will be too fast for me anyway !!. Cheers bill.

I needed the wheels rebuilt on my first Vincent in 1974 and was charged £14 labour each, that was a fortune to me then so after that I learnt to do it myself. What I haven't done yet is try to work out spoke lengths for myself, if I don't know I specify what they're for when I order them.

Chris.

Chris.