You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

David Bowen: Fishers Green

- Thread starter davidd

- Start date

G'day David,

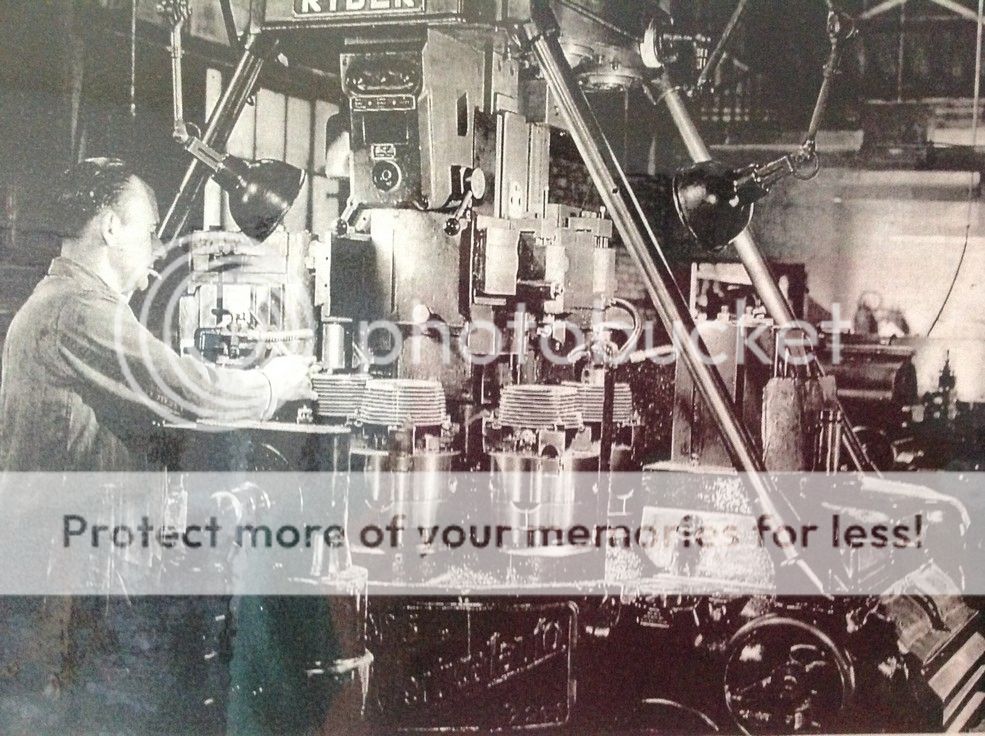

As a fitter and machinist these photos interest me intensely and gives insight into how the operations were carried out. Obviously the Ryder machines the cylinders but I'm trying to work out how the cylinders are held. It looks like they are being held by the top fin but surely this would not be sufficiently rigid to carry out machining of the sleeve bore and the stud holes and facing off of the cylinder base.

Phelps.

As a fitter and machinist these photos interest me intensely and gives insight into how the operations were carried out. Obviously the Ryder machines the cylinders but I'm trying to work out how the cylinders are held. It looks like they are being held by the top fin but surely this would not be sufficiently rigid to carry out machining of the sleeve bore and the stud holes and facing off of the cylinder base.

Phelps.

I would guess the chucks are closing on pre drilled holes for the thru bolts. Just a guess.

Jim Burgess

Jim Burgess

The following link is about George Barber:

http://homepage.ntlworld.com/john.barber27/

Thanks to Diogenes.

David

http://homepage.ntlworld.com/john.barber27/

Thanks to Diogenes.

David

Most of the machines were from the war effort Lease Lend

If you go to the image on the website that David has given, open up the work folder, right click on the image and select `copy image`. Open Accessories, then Paint, paste, and you will have a very good resolution picture, that shows the muffs being clamped down on the top fin.G'day David,

As a fitter and machinist these photos interest me intensely and gives insight into how the operations were carried out. Obviously the Ryder machines the cylinders but I'm trying to work out how the cylinders are held. It looks like they are being held by the top fin but surely this would not be sufficiently rigid to carry out machining of the sleeve bore and the stud holes and facing off of the cylinder base.

Phelps.

I just did all that and amazingly works as specified! More to the point I think you are right! How on earth did they keep it all square? Judging by the cylinder muffs I have seen most bores I have to be out of square..If you go to the image on the website that David has given, open up the work folder, right click on the image and select `copy image`. Open Accessories, then Paint, paste, and you will have a very good resolution picture, that shows the muffs being clamped down on the top fin.

Jim Burgess Norvin S.O.