Thanks Greg, I have heard of this "dipping process" before, and certainly i can see evidence of it on small parts like engine plates, brake plates, Girdraulic parts and the like. But i cant seem to understand how it would work with a set of cases...not only the masking but making the cases liquid tight for even partial submersion.......... i see not one drop of black paint squeezing thru on any of the shadow engine pieces. I feel we do not fully understand or appreciate this 1948 process. I have heard of paint floating on a bed of water and as you submerge the part and bring it up level , it adheres to the upper surface only. Maybe this "float" was part of the process? I just dont see masking and submerging engine parts as cost effective production practice.

What I can envision is "hand slathering" paint on pieces, rather than submersion, but what do I know.................we need help on this

But rather than get hung up on the process it self, i want to know what was masked and what was not masked to know how to cosmetically restore an old Shadow.

For instance, the timing cover does not appear to be masked at any of the external gasket surfaces like oil quill, oil filter, oil jet, mag hole...........but the large inside case gasket surface is no paint, no drips , perfect

Same with primary cases.

But the engine cases are much more complex and I would like a much more detailed understanding.

Thank you for helping with this

Craig

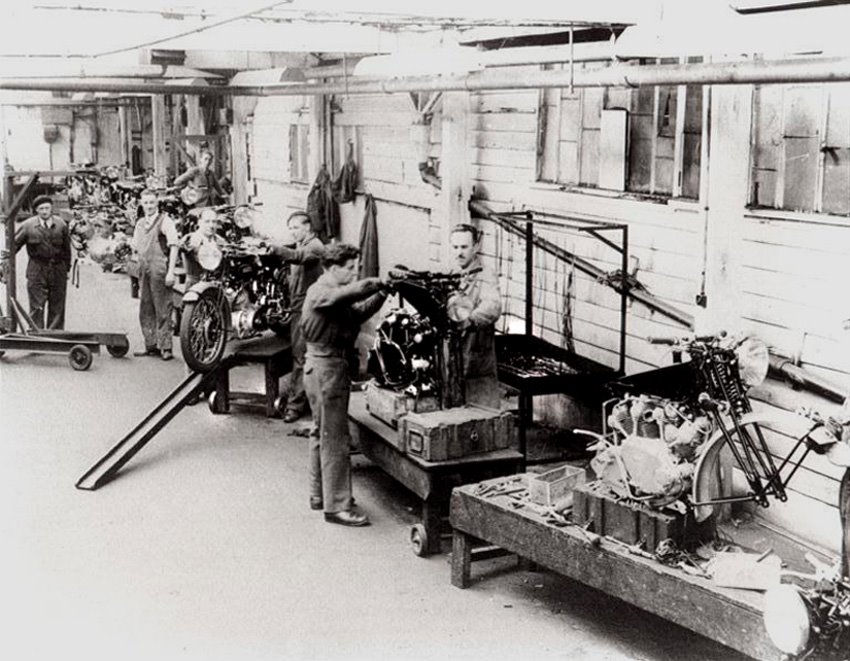

Regards to the painting of Shadow engines.....David Bowen told me that the case halves were bolted together with a few through bolts and cover plates screwed on over the timing, primary, cylinder spiggot holes, etc. other fittings and holes blanked off. Then the cases were lowered into a drum of black stove enamel, then left for a short period to drip off excess paint and then hung in a cabinet of some sort with a gas ring at the bottom to heat the cabinet and aid in the stoving of the paint. I think the heads and barrels were done in a similar way, but maybe with a different paint due to the heat these items would have to endure. I do not believe the parts were primed, rather the cases were etched using a solution they had available back then ( pylumenising) or whatever it was called. This would be a similar process as is used today on alloy aircraft sheet metal and other components which gives the surface a slight gold finish. It is more of a barrier to corrosion than anything. But the original finish would have been very thin, and yes the last part of the engine number was stamped on after painting, and the numbers touched up with a fine artists brush afterwards. I am unsure how the factory painted the outer covers, but i would have thought that they would have sprayed them to get a descent enough finish. It is a fair comment to say that almost all Shadows restored these days have a paint finish far more shiny and much thicker than the factory produced....well not to many folks have a spair drum of "Pinchin Johnsons" finest stove enamel kicking around in their sheds, do they......any thoughts.......Greg.