G

Graham Smith

Guest

Am busy rebuilding the engine on Joshua’s 1979 Yamaha RD125DX.

Unfortunately, one of the crank bearings is a bit loose in the case.

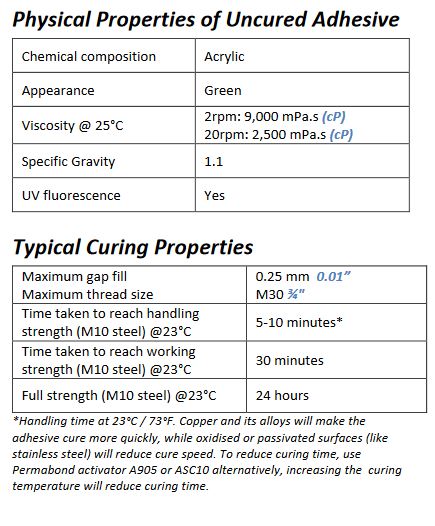

Am after suggestions for the best type of Loctite to use?

Unfortunately, one of the crank bearings is a bit loose in the case.

Am after suggestions for the best type of Loctite to use?