You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

identifying cams

- Thread starter redbloke1956

- Start date

My basket case came with some reground cams and no identification and I assumed that they would be MK 1 cams. The timing marks on the gears were not to be trusted so I spent many a happy hour twirling the engine around with a degree disk and pointer trying to identify opening and closing points. Eventually I found positions that I thought came closest to published figures. The engine started OK and has run thus for around 20,000 miles. A while ago (here or perhaps on another forum) in a discussion about cam timing Tom Gaynor said that he had found that bikes timed with equal lift around 4-6 degrees BTDC on the overlap gave good performance whatever the opening closing figures. When I subsequently check my timing using this method I found that I had indeed got equal valve lift around 4-6 degrees BTDC. Vibrac states in an earlier post in this thread that he also uses this method.

In the absence of identifying marks why not try the equal lift method and just check carefully that you have sufficient clearance everywhere.

In the absence of identifying marks why not try the equal lift method and just check carefully that you have sufficient clearance everywhere.

Last edited:

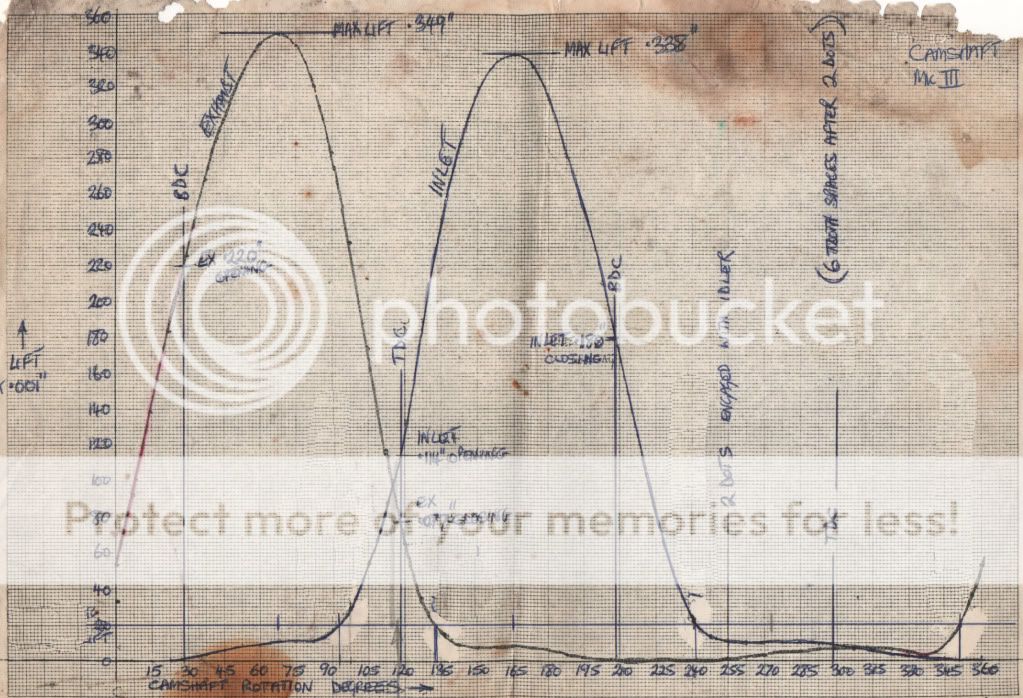

You can see from the graph I posted that equal lift is indeed a few degrees before TDC !!

Another easy method if you have no access to degree discs, dial gauges etc., is to set the inlet valve at .110" lift at TDC. Just set your tappet clearance to zero, get the piston to TDC ( use a small screwdriver down the plug hole !! ). Unscrew the tappet adjuster 3 full turns, then rotate the camshaft clockwise until the clearance is taken up. Insert the large idler !! Always more ways than one to skin a cat.

Cheers, Brian

Another easy method if you have no access to degree discs, dial gauges etc., is to set the inlet valve at .110" lift at TDC. Just set your tappet clearance to zero, get the piston to TDC ( use a small screwdriver down the plug hole !! ). Unscrew the tappet adjuster 3 full turns, then rotate the camshaft clockwise until the clearance is taken up. Insert the large idler !! Always more ways than one to skin a cat.

Cheers, Brian

Thanks Brian.

I think I'm too used to industrial cams. Graph demonstrates the quietening ramps well, it would be good to compare with Mk1, although I've used 1, 2 and 3 and they all clatter.

Re : why 105 degrees? Fastest piston speed should be 90 ATDC (or BTDC), my guess would be 105 is the fastest speed in the inlet tract, from memory it lags behind the piston speed, but I'm no expert (as I proved above).

H

I think I'm too used to industrial cams. Graph demonstrates the quietening ramps well, it would be good to compare with Mk1, although I've used 1, 2 and 3 and they all clatter.

Re : why 105 degrees? Fastest piston speed should be 90 ATDC (or BTDC), my guess would be 105 is the fastest speed in the inlet tract, from memory it lags behind the piston speed, but I'm no expert (as I proved above).

H

Thats the joy of the EQUAL lift method you measure when the cams are most active ie on the flanks. My method is to pop the cam (one at a time) in at approximately the right place by eye (Who could trust a timing mark after 60 years? ) then again by feel I turn engine around TDC till the valve 'feel' equally lifted (changing the position is relatively easy) then you can put dial guage's to work,I dont use them now since I find myself unable to look at a moving clock and anti clock set of dials at the same time and be sure of what is what. So I find the best method is to measure the slack spring height of the inlet and exhaust valve (they rarely are the same) and add some washers on top of the 'low' ET37 to make the exactly the same height sticking them with a blob of Plasticine.My question in this thread is, how do you set the point of highest lift? Surely there are several degrees at the top of the cam lobe where the lift is constant, a graph of the valve opening (time vs lift) will have a flat top, not a point.

H

Then its a simple matter to start at say 20 deg before TDC and measure the inlet opening and the exhaust closing with a digital depth guage when they are spot on equal (perhaps somewhere in the .300-.400 thou range) have a look at the degree plate. if it reads 6 deg before TDC-(it never is first time) job done.except if you have a twin you need to repeat the job and I have no doubt compromise in your settings my notes say last time I got 8 on the rear and 5 on the front -my best effort ever.

This may sound a bit odd to those brought up on Tuning for speed but after all unless you are actually modifying your cam shafts the lift and duration are already set in hardened steel why bother with them. the feast is already made all you can do is move it. And the sweet moment to measure is when the inlet starts to breath AND the exhaust is running out of puff

Because it's 20 years since I last set the valve timing, I've been puzzling all day how I did it.

I think this was my method:-

Assume one cam for now. Note the theoretical opening and closing points (from the red book), which are (I found) impossible to locate in practice.

Adjust tappet tight. Turn the crank until the valve starts to open and note the lift (dial gauge) and crank angle (degree plate). Turn the crank until the dial gauge reads the same lift and note the degrees. The cam needs to be adjusted until this angle is mid way between the theoretical open to closed angle.

I set the inlet, and let the exhaust look after itself (within reason).

Looking at this, I think I'm setting based on the maximum lift after all.

It seems to have worked for me.

H

I think this was my method:-

Assume one cam for now. Note the theoretical opening and closing points (from the red book), which are (I found) impossible to locate in practice.

Adjust tappet tight. Turn the crank until the valve starts to open and note the lift (dial gauge) and crank angle (degree plate). Turn the crank until the dial gauge reads the same lift and note the degrees. The cam needs to be adjusted until this angle is mid way between the theoretical open to closed angle.

I set the inlet, and let the exhaust look after itself (within reason).

Looking at this, I think I'm setting based on the maximum lift after all.

It seems to have worked for me.

H