Never have this problem with my "Bender sidecar" attached! But seriously,I am not strong enough to lift the front of the solo bike up using the 2 front stands in the down position! I use a centre stand [U.K. spelling] and prop a special piece of wood-being a woodworker-to keep the front wheel off the ground.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front Stands

- Thread starter DangerDan

- Start date

Thanks Paul, why are you not producing this FT118 casting and selling for 200GBP? I don't want bent or extended side stands or a piece of wood or a local rock or a suitable tree or rear stand.

I like this idea! what are the pegs for?

Cheers

Craig

I like this idea! what are the pegs for?

Cheers

Craig

Craig,

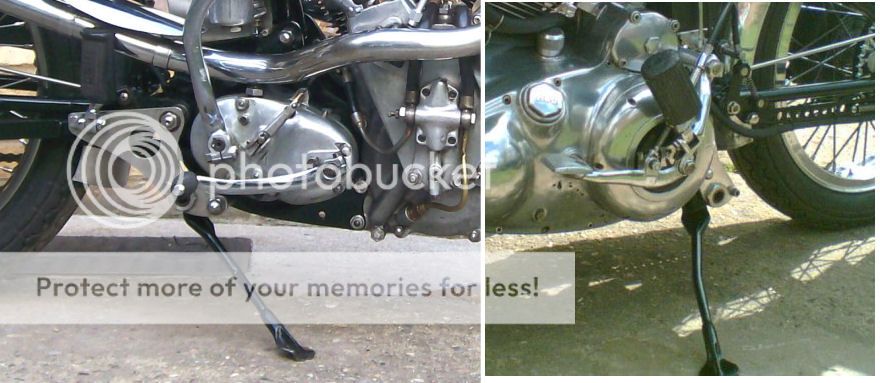

I made that front stand bracket from a 'one-off' casting based on an idea in MPH (Bert Weiss, I think) to cut the existing casting and re-weld the stand lugs at 10* from the vertical. Those details are in FYO.

Paul.

Last edited:

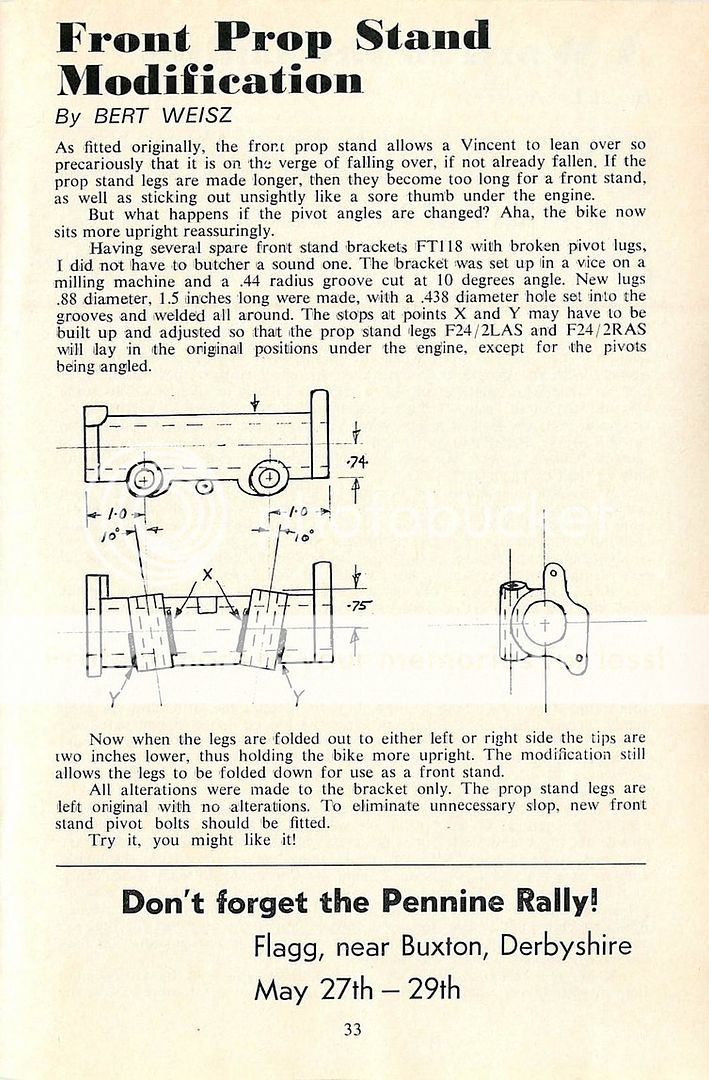

The relevant details for the mod recommended by Bert Weisz, referred to and illustrated by Paul, is in MPH 352, May 1978, page 33, or alternatively in Forty Years On, page 20, Item 74.

The relevant details for the mod recommended by Bert Weisz, referred to and illustrated by Paul, is in MPH 352, May 1978, page 33, or alternatively in Forty Years On, page 20, Item 74.I can also vouch for the improvement offered by this modification. My propstands work as desired in all respects.

Last edited:

You mean this improved FT118 was designed 35 years ago and no one is providing these FT118 today! We are still looking for rocks/sticks by the side of the road!

View attachment 1686The relevant details for the mod recommended by Bert Weisz, referred to and illustrated by Paul, is in MPH 352, May 1978, page 33, or alternatively in Forty Years On, page 20, Item 74.

I can also vouch for the improvement offered by this modification. My propstands work as desired in all respects.

Craig,

With the propstand pivots angled at 10º, when you use them as a front stand to remove the front wheel they splay out too far. My solution was to make those two pegs that fit into the magneto cowl fixing slots and provide stops that keep the stand in an effective position. They reside in the tool tray until needed.

The story of the casting is that a Coventry section member had a pattern made and produced two stand brackets in alloy for his and his son's bikes. The machining involved prevented the project from becoming a semi-commercial venture, but he did have another bronze casting available which I aquired and machined as per the photograph.

Cheers,

Paul.

With the propstand pivots angled at 10º, when you use them as a front stand to remove the front wheel they splay out too far. My solution was to make those two pegs that fit into the magneto cowl fixing slots and provide stops that keep the stand in an effective position. They reside in the tool tray until needed.

The story of the casting is that a Coventry section member had a pattern made and produced two stand brackets in alloy for his and his son's bikes. The machining involved prevented the project from becoming a semi-commercial venture, but he did have another bronze casting available which I aquired and machined as per the photograph.

Cheers,

Paul.

Last edited by a moderator: