Gentlemen,

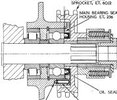

May I have your expert opinions as to how close a fit should be the ET77 Mainshaft Oil Scroll (called Main Bearing Distance Piece in the Parts List) in the ET19 Main Bearing Spacer ?

I have two used ones available, one 1.3580", the other 1.3585", but both are slightly sloppy in the ET19. Given that ET77 plays a part in oil control, should the fit be as close as possible but still allowing free rotation, or will a used one suffice? How quickly will a new one wear down to the same dimension as the ones I have already?

Would too good a fit reduce the oil supply to the outer main bearing to ill effect?

Does anyone have a new one handy that they could measure?

Many thanks.

Rapcom

May I have your expert opinions as to how close a fit should be the ET77 Mainshaft Oil Scroll (called Main Bearing Distance Piece in the Parts List) in the ET19 Main Bearing Spacer ?

I have two used ones available, one 1.3580", the other 1.3585", but both are slightly sloppy in the ET19. Given that ET77 plays a part in oil control, should the fit be as close as possible but still allowing free rotation, or will a used one suffice? How quickly will a new one wear down to the same dimension as the ones I have already?

Would too good a fit reduce the oil supply to the outer main bearing to ill effect?

Does anyone have a new one handy that they could measure?

Many thanks.

Rapcom