I am trying to sort out a Burman clutch in a 1951 Comet. I purchased a Conway Honda clutch kit and installed after much needle filing. I fit a new primary chain. Purchased new cable, unsoldered the funnel end, cut off some cable housing, resolderd the "funnel" fitting.

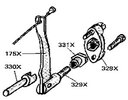

Now i am at the point of deciding how much clutch rod to have as the stock rod is too long and could be cut to fit the new Honda clutch. I notice the adjuster threads are fully sticking out of 331X nut, so i look at another Comet Burman and the threads are about even with end of nut , i look at friends Burman Comet and same thing, even at end. So i adjust the one i am working on to even end thread and the clutch handle at the handlebar will no longer swing with any travel, as it had been. Flashlight in the Burman shows that the clutch lever 175X has been flipped around and is now too close to the mainshaft! This flip had created a problem for the past worker and i noticed the 331X nut was ground off (on the interior surface) to allow more distance out of the case with this flipped lever assembly!

Question is - Is a flipped clutch lever a common item for a mechanic to consider when servicing a Burman? What does this flipped lever accomplish?

Is this just a mechanic mistake that kinda works (after you grind the nut off)?

thanks for any help

Craig

Now i am at the point of deciding how much clutch rod to have as the stock rod is too long and could be cut to fit the new Honda clutch. I notice the adjuster threads are fully sticking out of 331X nut, so i look at another Comet Burman and the threads are about even with end of nut , i look at friends Burman Comet and same thing, even at end. So i adjust the one i am working on to even end thread and the clutch handle at the handlebar will no longer swing with any travel, as it had been. Flashlight in the Burman shows that the clutch lever 175X has been flipped around and is now too close to the mainshaft! This flip had created a problem for the past worker and i noticed the 331X nut was ground off (on the interior surface) to allow more distance out of the case with this flipped lever assembly!

Question is - Is a flipped clutch lever a common item for a mechanic to consider when servicing a Burman? What does this flipped lever accomplish?

Is this just a mechanic mistake that kinda works (after you grind the nut off)?

thanks for any help

Craig

Attachments

Last edited: